TrustLink Metal Shell Connectors Handling Instructions

Follow these instructions carefully to ensure correct use of your TrustLink connector.

TrustLink CCP to FCR, BCR receptacle

Step 1: Inspect the connector metal parts and O-rings for contamination. Grease the O-rings with Molykote 111

Step 2: Inspect the connector insert. If the connector insert is contaminated, follow the TrustLink MS maintenance

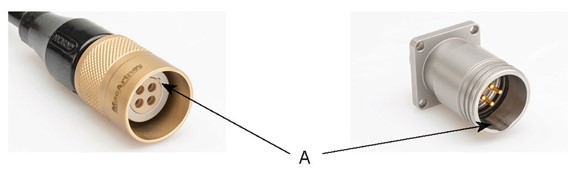

Step 3: Visually align the key way on the CCP connector with the key pin tip on the receptacle before mating (illustration A)

Step 4: Push to mate the connector, whilst turning the locking sleeve

Step 5: The locking sleeve must be hand tightened only

NOTE: When dismounting the CCP, vacuum may accrue in the connector. It can cause water from above the O-rings, to migrate in to the connection area. If that accrues, run the maintenance instruction.

Maintenance

- If the connector insert or O-rings are contaminated. Cleaning and removal of any accumulated contamination on a connector, should be performed by using spray based contact cleaner (isopropyl alcohol)

- Repeat the cleaning process if necessary

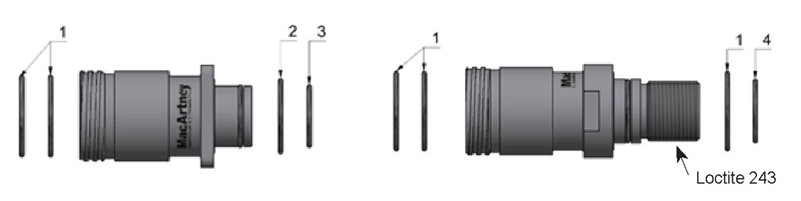

- O-rings item 1, 2, 3, 4 must be checked before mating/mounting and will require replacing if they show signs of damage

- Sizes of O-rings can be found in the assembly instructions on our webpage

- Always grease O-rings with Molykote 111

- For securing the BCR connectors and nut, the use of Loctite 243 is recommended (Loctite 243 or equivalent) If the torque is less as recommended, always use Loctite 243

- Be careful not to get the Loctite on the O-rings

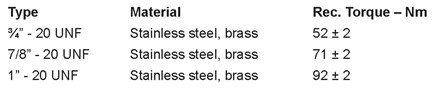

Recommended torque on Bulkhead TrustLink MS (Loctite 243 applied)

The TrustLink Metal Shell series is rated to 600 bar mated.